World-leading Brink® fiber bed mist eliminators are used around the world for the effective elimination of fine aerosol mists, submicron oil smoke and soluble solids. Brink® solutions deliver the highest efficiencies, lowest pressure drop, and longest effective life available.

Brink® fiber bed mist eliminators are designed to remove virtually any type of mist from any gas stream and they excel at collecting the most difficult to capture aerosol mists – submicron sized. Since their development by Dr. Joseph Brink in 1958 to address air pollution issues in phosphoric acid plants, this custom engineered technology has found application at more than 5,000 facilities around the world and is used by a broad range of industries, from sulfuric acid to asphalt manufacturing, green hydrogen, plastic extrusion, metalworking and many more. Our solutions protect valuable downstream equipment, optimize operations, and minimize environmental impact, while delivering the highest efficiency.

Our engineers can help your organization select and optimize a Brink® solution for your application needs, whether you wish to improve process equipment design, operation, and product quality, or seek to reduce stack opacity to avoid environmental citations. Whatever your needs, in-process or end-of-process Brink® mist eliminators can help you achieve the highest performance, while lowering plant maintenance and operating costs.

Removal of small and submicron particles that have the greatest tendency to cause opacity and plume persistence in stack gases. Brink® mist eliminator systems effectively remove these particles eliminating visible as well as harmful air pollution.

Removal of harmful mists that can cause downstream corrosion, plugging or fouling. Brink® mist eliminator units are self-cleaning, have no moving parts, and seldom require repacking. (One client operated over 24 years before repacking).

MECS® Brink® mist eliminators offer superior service life. Whether for sulfuric acid plants, chlorine plants, engineered package systems, or other industrial processes, MECS® Brink® mist eliminators have a solid history of robust and sturdy mechanical construction, whatever the service environment may be.

Removal of contaminating mists and soluble solids at collection efficiencies of nearly 100 percent. As the particle size gets smaller (below three microns and in the sub-micron ranges), Brink® mist eliminator efficiencies actually increase. One application in cryogenic helium reported mist removal down to the parts per billion level.

Often a side benefit of a Brink® mist eliminator system installed for some other reason, reduced material losses can partially offset or even completely pay for the system.

Removal of dangerous mists that create potential fires or explosions in process gas streams and compressed air systems.

Removal of submicron mists in a process gas stream can eliminate the need for more costly materials of construction for downstream equipment and permit more efficient operating conditions that increase product yield.

There are several Brink® mist eliminator diffusion fiber bed types that can be used for your process. Depending on the application, as much as 40% lower pressure drop can be achieved for the same collection efficiency when compared to older fiber bed technologies.

As with all Brink® mist eliminators, diffusion beds provide collection efficiencies of 100 percent on all particles larger than one micron in diameter. Diffusion bed systems can also be designed to provide collection efficiencies as high as 99.999+ percent on all particles less than one micron in diameter for special applications.

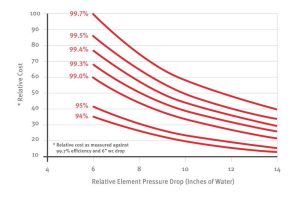

Typically, collection efficiencies of 94 to 99.7 percent on all particles one micron and smaller in diameter are utilized in Brink® mist eliminator systems. Our diffusion bed mist eliminators are designed for a specified pressure drop, usually in the range of two to 20 inches of water column. Since pressure drop is proportional to fiber bed area, the size and cost of a Brink® diffusion fiber bed increases for lower designed pressure drops and higher collection efficiencies. The figure below shows the effect of pressure drop and collection efficiency on the cost of Brink® mist eliminator diffusion fiber beds for a given gas flow.

Typically, collection efficiencies of 94 to 99.7 percent on all particles one micron and smaller in diameter are utilized in Brink® mist eliminator systems. Our diffusion bed mist eliminators are designed for a specified pressure drop, usually in the range of two to 20 inches of water column. Since pressure drop is proportional to fiber bed area, the size and cost of a Brink® diffusion fiber bed increases for lower designed pressure drops and higher collection efficiencies. The figure below shows the effect of pressure drop and collection efficiency on the cost of Brink® mist eliminator diffusion fiber beds for a given gas flow.

NOTE: Collection efficiencies in all Brink® mist eliminator systems are measured on a weight basis by particle size. Brink® systems can be designed to meet varying client needs, with collection efficiencies of 100 percent on all particles larger than one micron in diameter and as high as 99.999+% on all particles less than one micron in diameter.

We select the optimum fiber bed design for your process to minimize total cost. Note that in addition to up-front capital cost, the overall life cycle cost of mist eliminators includes operating pressure drop (energy consumption) and the cost of maintenance. Often it is better to include extra operating margin in the mist eliminators to extend service life rather than trying to find the lowest cost installation.

For minimum overall life cycle cost, it is important when purchasing a fiber bed system to balance collection efficiency, operating pressure drop, and product service life. Brink® mist eliminator application experience in over 300 applications with over 5000 installations world-wide will help assure your fiber bed design will provide balanced, state-of-the-art performance for your peace of mind.

For details on how our MECS® Brink® fiber bed mist eliminators work, please see our brochure.